Welders

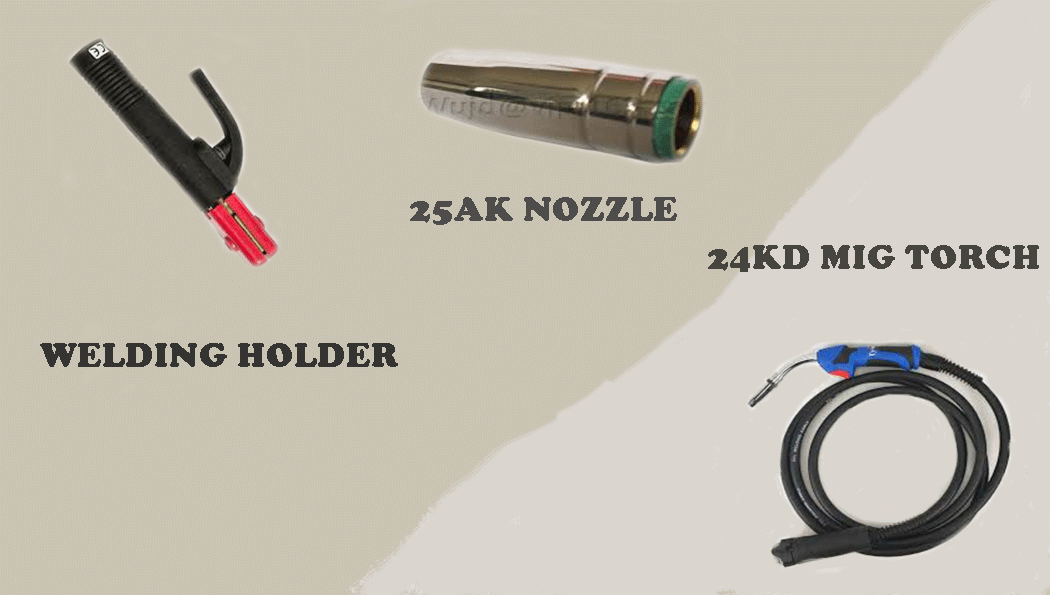

The voltage power, AC/DC settings, and duty cycle are some of the most important factors to consider when choosing a welder. The welder will need both the power and a sufficient operating time (the duty cycle) in order to complete every project. Choosing between stick, MIG, and TIG welders is a matter of balancing cost, skill, portability, convenience, and the nature of the project. MIG welding is simple to use, but it is costly and not as portable as the simple stick welding process. TIG welding creates high quality, clean welds, but it is much more difficult to learn.

Read Baker’s Guide to Choosing a Welder

Electrodes

There are specific electrodes that match each of the three main welding processes. Stick welding uses a consumable electrode that is melted in order to create the weld joint. The E6010 electrode is one of the most popular electrodes, though the E6011, E6013, and E7018 are frequently listed by welders as excellent choices.

MIG welding uses a consumable electrode wire that is fed through the welding torch. Most projects use wire in the following range of thickness: .023, .030, .035, and .045, though a thicker wire may be needed for larger projects.

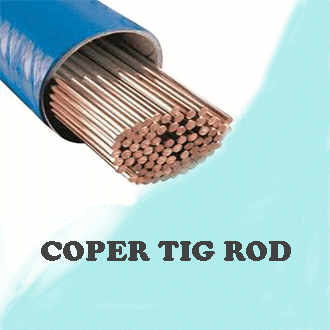

TIG welders use non-consumable electrodes that come in five main varieties. Ceriated and lanthanated electrodes are both good choices for most TIG welding applications. Avoid thoriated electrodes since they emit radiation when used and require a respirator.

Read Baker’s Guide to Choosing the Best Electrode

admin

Cras sollicitudin, augue eu dictum posuere, ligula arcu tincidunt urna, ut congue risus urna at enim. Nunc sagittis metus vitae enim vestibulum facilisis.